Change in Process Reduces costs by 42%

This specific part was a performance fitment part. These require tight tolerances and more precision.

We suggested changes in the PPAP (Production Part Approval Process) which helped reduce the number the steps in operation from 7 to 4.

This drastically reduced cycle time which reduced manufacturing and conversion costs by up to 42%.

We manufacture performance fitment parts for engineering industries like the automotive and aerospace industry, etc on a regular basis.

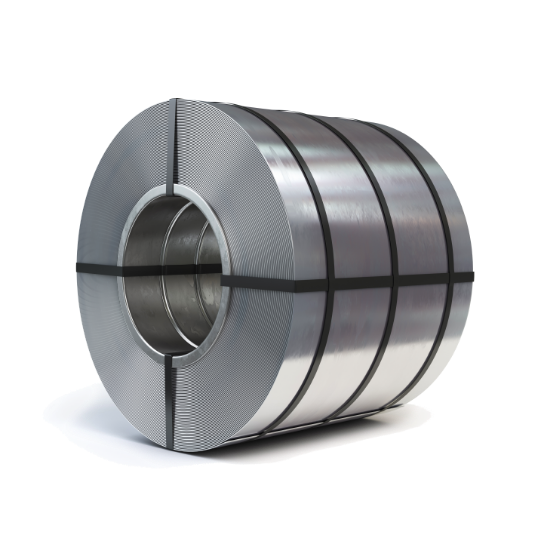

Here, for this specific case study, we used mild steel sheet metal or cold-rolled steel.